Arc Welding Equipments

Some very important items used by a welder with an arc welding machine during

the welding operation, are called arc welding accessories.

- Electrode holder

- Earth Clamp

- Welding cables/ leads

Electrode holder

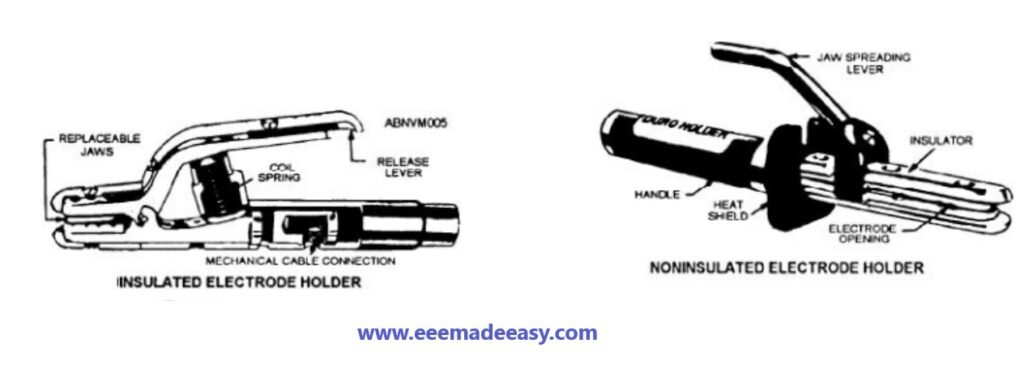

Electrode holder is a clamping device used to grip and manipulate the electrode during arc welding.

It is made of copper/ copper alloy for better electrical conductivity. Partially or fully insulated holders are made in various sizes i.e. 200-300-500 amps.

The electrode-holder is connected to welding machine by a welding cable.

Download & Install EEE Made Easy App

Earth Clamp

It is used to connect the earth cables firmly to the job or welding table. It is also made of copper/ copper alloys.

Screw or spring loaded earth clamps are made in various sizes i.e. 200-300-500 amps

Welding cables/ leads

These are used to carry the welding current from the welding machine to the work and back.

The lead from the welding machine to the electrode-holder is called electrode cable and the lead from the work or job through the earth clamp to the welding machine is called earth (ground) cable.

Cables are made of super flexible rubber insulation, having fine copper wires and woven fabric reinforcing layers. Welding cables are made in various sizes (crosssections) i.e. 300, 400, 600 amps etc.

The same size welding cables must be used for the electrode and the job.

The cable connection must be made with suitable cable attachments (lugs).

Loose joints or bad contacts cause overheating of the cables.

MATERIAL PREPARATION METHOD

Welding material preparation Methods are,

- cutting

- Cleaning

Cutting

Cutting and preparing the base metal to the required dimensions from the original material available is necessary before welding them.

Different methods used to cut metals are:

- By chiseling the sheets

- By hack-sawing

- By shearing using hand lever shear

- By using guillotine shear

- By gas cutting

For thin sheets the first 4 methods are used. For thick materials method 2, 4 and 5

are used.

Tools and equipments used to cut metals

- Cold chisel

- Hacksaw with frame

- Hand lever shear

- Guillotine shear

- Oxy-acetylene cutting torch

The cut edges of the sheet or plate are to be filed to removed burrs and to make

the edges to be square (at 90° angle) with each other.

For ferrous metal plates, which are

more than 3mm thick, the edges can be prepared by grinding them on a bench/ pedestal

grinding machine.

Cleaning

The base metals before cutting them to size will have impurities like dirt, oil, paint, water and surface oxides, due to long storage.

These impurities will affect the welding and will create some defects in the welded joint. So in order to get a strong welded joint, it is necessary to clean the surfaces to be joined and remove the dirt, oil, paint, water, surface oxide etc. from the joining surfaces before welding.

Importance of cleaning

The basic requirement of any welding process is to clean the joining edges before

welding.

The joining edges or surfaces may have oil, paint, grease, rust, moisture, scale

or any other foreign matter.

If these contaminants are not removed the weld will become porous, brittle and weak.

The success of welding depends largely on the conditions of the surface to be joined before welding.

Methods of cleaning

- Chemical cleaning includes washing the joining surface with solvents of diluted hydrochloric acid to remove oil, grease, paint etc.

- Mechanical cleaning includes wire brushing, grinding, filing, sand blasting,scraping, machining or rubbing with emery paper.

- For cleaning ferrous metals a carbon steel wire brush is used.

- For cleaning stainless and non-ferrous metals, a stainless steel wire brush is used.

Read more on Electric Welding

- [Set 2]MCQ’s on Electrical Welding|Electrical Welding MCQ Questions and Answers|KSEB Sub Engineer

- [Set 1]MCQ’s on Electrical Welding|Electrical Welding MCQ Questions and Answers|KSEB Sub Engineer

- Electric Welding|Resistance welding Electric Arc Welding

- Resistance Welding|Types of Resistance Welding

- Electric arc welding|Types of Electric Arc welding

- Electric Arc length|Short,Medium, Long Arc

- Open Circuit voltage and Arc voltage|Polarity in arc welding

- Arc Welding Equipments|Arc Welding tools and Accessories

- Arc welding safety|shielded metal arc welding preparation & safety

- Methods of joining metals|Metal Joining Methods

- Types of welds|Weld types

- Applications of Welding|Welding Applications

Books on Welding

Join EEE Made Easy Telegram channel

Latest Posts in EEE Made Easy

- Environment MCQ for RRB JE CBT 2|Objective Questions Environment for Competitive Exams

- RRB JE CBT 2 Computer Awareness Book Arihant|Objective Computer Awareness Book 2025

- RRB JE CBT 2 Exam Date 2025 Postponed|RRB JE CBT 2 Exam Date

- [PDF]RRB JE Result 03/2024 Cut off, Selected no of candidates for all regions

- [PDF]Final Answer Key Junior Instructor Mechanic Agricultural Machinery|643/2023 Solved Question paper

- Acoustics MCQs|Industries Extension officer|IEO 2025

- LASER MCQs| Industries Extension officer|IEO 2025