Conductor Materials for conducting electric current

The conductor materials used for transmission and distribution of electrical energy must have the following characteristics.

Characteristics of good conductor materials are;

- It should have a low cost.

- It should be light in weight

- It should have high conductívity.

- It should not be brittle

- It should have a high tensile strength to withstand mechanical stresses.

- Low specific gravity in order to give low weight for unit volume.

- If you want to know about Magnetic materials, read HERE

Aluminum, Copper, and galvanized steel conductors are generally used for the transmission and distribution of electrical energy.

The conductor materials are,

(1) Copper

The resistivity of annealed high conductivity copper is 0.01724 W-m/mm2 at 20°C.

The electrical resistance of copper varies with temperature.

High conductivity copper is available in the form of fully annealed or the hard drawn state depending on the properties required for the items under manufacture.

Hard drawn copper is having double, the tensile strength of annealed copper.

Insulated cables consist of annealed copper whereas overhead lines consist of hard drawn copper.

The busbars for heavy current conductors of relatively short

length is made o1 hard drawn copper.

(2). Aluminium.

Aluminum is replacing copper in many of its applications.

It has a conductivity of 62% that of copper.

In high voltage transmission line aluminum is used as supports, conductors and conductor accessories.

Aluminum is also used as the conductor for distribution cable.

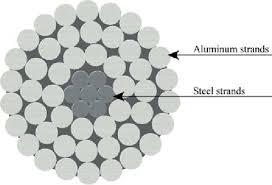

(3) Aluminium Conductor Steel Reinforced (A.C.S.R).

These conductors are used for long-distance high voltage overhead transmission lines.

A.C.S.R. consists of a core of galvanized steel strand surrounded by a number of aluminum strands.

The core is galvanized steel to prevent rusting and electrolytic corrosion. The steel core takes a greater percentage of mechanical stresses and the aluminium carries the current. A.C.S.R. conductors have high tensile strength.

(4) Cadmium copper alloys.

Cadmium copper alloy contain 0.6 to 1% cadmium when cadmium copper is hard drawn.

Its tensile strength is 50% greater than that of hard drawn copper.

It is used for overhead lines and for contact wires for overhead lines.

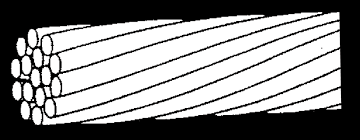

Advantages of Stranding the Conductors

Stranding of conductors

(1) They are more flexible and durable, therefore, can be handled conveniently.

(2) The surface area of stranded conductor is more as compared to the surface area of an equivalent single solid conductor.

As the heat radiating capacity is proportional to the surface area, therefore, a stranded conductor has more heat radiating capacity as compared to a single solid conductor.

Also Read;

Basic Electrical Engineering Expected Questions

Basic Electrical Engineering MCQ

CELLS and Batteries notes

- Environment MCQ for RRB JE CBT 2|Objective Questions Environment for Competitive Exams

Environment MCQ for RRB JE CBT 2: In this post, a list of posts with Objective Questions Environment for Competitive … Read more

Environment MCQ for RRB JE CBT 2: In this post, a list of posts with Objective Questions Environment for Competitive … Read more - RRB JE CBT 2 Computer Awareness Book Arihant|Objective Computer Awareness Book 2025

RRB JE CBT 2 Computer Awareness Book Arihant: you can Master Computer Awareness with the Revised edition of Computer Awareness … Read more

RRB JE CBT 2 Computer Awareness Book Arihant: you can Master Computer Awareness with the Revised edition of Computer Awareness … Read more - RRB JE CBT 2 Exam Date 2025 Postponed|RRB JE CBT 2 Exam Date

The Railway Recruitment Board (RRB) has announced the postponing the exam schedule for Junior Engineer positions under CEN No. 03/2024. … Read more

The Railway Recruitment Board (RRB) has announced the postponing the exam schedule for Junior Engineer positions under CEN No. 03/2024. … Read more - [PDF]RRB JE Result 03/2024 Cut off, Selected no of candidates for all regions

The RRB JE Result 2025 was released on March 5, 2025, for 7,951 positions on the official website. Candidates can … Read more

The RRB JE Result 2025 was released on March 5, 2025, for 7,951 positions on the official website. Candidates can … Read more - [PDF]Final Answer Key Junior Instructor Mechanic Agricultural Machinery|643/2023 Solved Question paperFinal Answer Key Junior Instructor Mechanic Agricultural Machinery Question Paper Code: 7/2025/OLCategory Code: 643/2023Exam: Junior Instructor Mechanic Agricultural MachineryDate of … Read more