Construction and Operation of Evaporators-|Dairy Engineering|Technical Superintendent milma|Technical Superintendent Milk Marketing Federation Limited

Kerala PSC is conducting Exam of Technical Superintendent Milk Marketing Federation Limited(MILMA). The Milma Technical Superintendent Exam will be on 19 February 2020. All candidates need to give the confirmation before December 12. The study materials of technical superintendent Milma can be got from eee.bibimohanan.com, www.eeemadeeasy.com and video classes will be available in the YouTube Channel EEE Made Easy. You can follow the EEE Made Easy Telegram channel to get updates of the exam for the post of Technical Superintendent Milk Marketing Federation Limited.

Evaporators

What is an Evaporator? Need of Evaporator in Dairy Plants

A number of evaporators of different designs have been developed.

The need of large scale operation and of improvement in quality has replaced the batch type evaporators.

We shall discuss here the most important types of evaporators that are of interest to the dairy industry.

EVAPORATOR SYSTEMS

Basically, an evaporator system consists of ;

- a heat exchanger, supplying the sensible heat to raise the product to its boiling point and provide the latent heat of vaporization,

- a separator for the separation of vapour and concentrate,

- a condenser to remove the resultant vapour as condensate and a vacuum system as the process is carried out under reduced pressure.

The heating medium is steam.

For vacuum, barometric leg condenser, vacuum pump and steam ejector are generally used.

The evaporators may employ natural or forced circulation of the product.

In natural circulation units, the circulation of the liquid is brought about by convective currents arising from the heating surface.

In forced circulation evaporators, the increased velocity of the liquid over the heat transfer surface will bring about a marked increase in the liquid heat transfer coefficients.

The circulation is achieved with the aid of an external circulating pump generally a centrifugal pump.

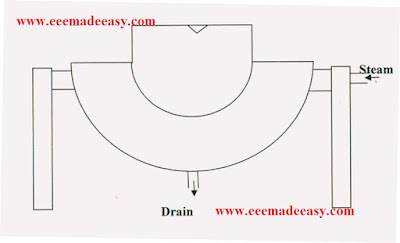

The simplest evaporator as shown in the above figure consists of an open pan and kettle in which liquid is boiled.

The heat is supplied by condensation of steam on one side of a metal surface and the liquid material to be evaporated on the other side.

Sometimes heating coils immersed in the liquid.

In some cases, the kettle is indirectly fired.

These evaporators are inexpensive and simple to operate, but the heat economy is poor.

Paddles and/or scrapers are used to improve the economy and quality of the product.

Based on the nature of the heat transfer surface, evaporators can be classified as:

(1) Tubular surface with natural or forced circulation.

a. Horizontal tube evaporator

b. Vertical short tube evaporator

c. Falling film evaporator

d. Rising /Ascending/climbing film evaporator

(2) Flat heating surface: plate evaporator

(3) Stationary cylindrical surfaces with scraped surface evaporator.

You can follow EEE Made Easy Telegram channel

Dairy Engineering More Notes

- Types of Dairies

- Importance of Dairy Plant Design

- Feeding System in Dairy Plant

- Classification of Dairy Plants

- Basic Principles of Evaporators

- Technical Superintendent Milma Syllabus

- Technical Superintendent Milma Previous Question paper

- Dairy Engineering MCQ questions 1

- Dairy Engineering MCQ questions 2

- Dairy Engineering MCQ questions 3

- Dairy Engineering MCQ questions 4

- The Technology of Milk and Milk products/ Technology of Butter making

- Butter making in Batch Churn

- Continuous Butter Making

- Ice cream FSSAI standards

- Indigenous Milk products Sweets

- Quality Assurance Standards of milk Products

- Air Heating Systems of Dairy Plant

Also Check;