DOL Starter or Direct on line Starter is a starting method used for Induction Motors. DOL Motor is also knows as “across the line starter”. Direct on line Starter is a device consisting of a main contactor, protective devices and overload relay which is used for motor starting operations. DOL Starter is used for low rating usually below 5HP motors.

Direct on line Starter

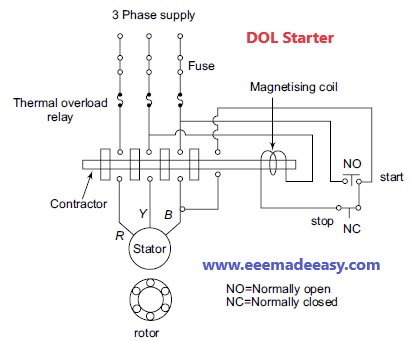

The schematic diagram of an induction motor with direct-on-line (DOL) starter is shown in Figure

dol starter diagram

The main purpose of this starter is to protect the induction motor from different abnormal conditions like over-voltage, low voltage etc.

It is used in the induction motor whose capacity is less than 5 Horsepower.

Since the starting current in this capacity motor is less, a DOL starter applies rated voltage to the stator winding.

The normal open and normal close contacts in a DOL starter represent the normally open switch and normally closed switch.

These contacts are used to start and stop the induction motor respectively.

A small cage induction motor may be switched \direct-on-line,” meaning that it is switched directly onto normal voltage, momentarily taking several times the full-load current at a low power factor.

Direct switching may be the subject of Supply Authority regulations. However, there is usually no restriction on small induction motors up to 5.5 kW.

The various starters which are employed to restrict the initial rush of current in squirrel cage induction motors are Direct On Line (D.O.L.) Starter, Primary resistance (or inductance) starter, Star/Delta Starter, and Auto-transformer Starter.

Direct on Line (D.O.L.) Starter It is a starter by which the motor is switched ON direct to the supply mains by switching conductor.

With normal industrial motors this operation results in a heavy rush of current of the order of five to seven times of the normal full load current.

This high current rapidly decreases as the motor picks up speed but it is at a very low power factor and thus tends to disturb the voltage of the supply in the distribution lines.

For this reason, the supply authorities limit the size of motor upto 5 H.P. which can be started by this starter.

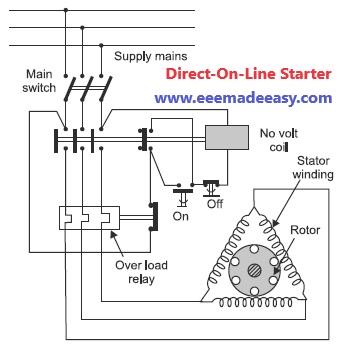

Automatic DOL starter diagram

An automatic D.O.L. Starter is shown in Fig.

A direct on line starter essentially consists of a contactor having four normally open (N.O.) contacts and a contactor coil also known as no-volt coil or no volt release.

There are two push buttons ON and OFF which are used to start and stop the motor.

To protect motor against overload, thermal or magnetic over-load coils are connected in each phase.

To start the motor, the ON push button (green) is pressed which energies the no-volt coil by

connecting it across two phases.

The no-volt coil pulls its plunger in such a direction that all the normally open (NO) contacts are closed and motor is connected across supply through three contacts.

The fourth contact serves as a hold on contact which keeps the no-volt coil circuit closed even after the ON push button is released.

To stop the motor, OFF push button (red) is pressed momentarily which de-energises the no volt coil opening the main contacts.

When the motor is over loaded, the thermal overload relay contact, connected in the control

circuit opens thus disconnecting the No-volt relay from the supply.

Overload protection is achieved by thermal element overload relay.

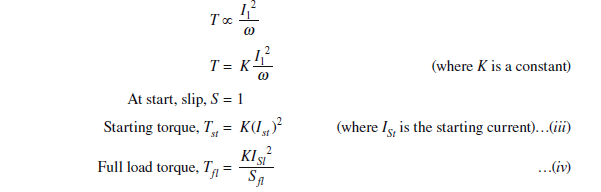

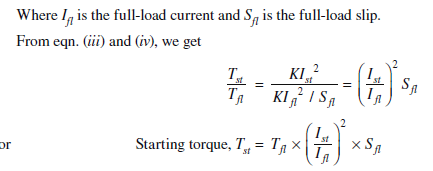

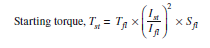

Torque developed by the motor when started by direct on line starter:

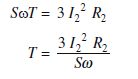

Power developed in the rotor or rotor input = wT

Rotor copper loss = S x rotor input

= SwT

Also rotor copper loss = 3 I22 R2

Where S is the slip, is the angular velocity, T is the torque developed, I2 is the rotor current per

phase and R2 is the rotor resistance per phase.

Equating the eqn. (i) and (ii), we get,

since rotor resistance and supply frequency is constant.

As stator current is proportional to rotor current,

i.e.,

When motor is connected to the mains by direct on line starter, the starting current of the motor

will be equal to the short-circuit current Isc

Read more on DC Machines

- Armature Reaction MCQ|DC Generator MCQ Questions|DC machines

- DC Machines Questions and Answers|DC Machines MCQ

- D.C Machines|What is a DC machine

- Armature Reaction in DC Machines|Cross Magnetization and Demagnetization

- 50 MCQ questions on DC Motor|Electrical Machines MCQ Questions and answers|DC Motor MCQ

- MCQs on DC Motor Tests|Tests on DC Motor Objective Questions

- Speed Control of D.C Motor MCQ Questions|Objective Questions on DC Motor Speed Control

- DC motor objective questions for Industrial extension officer ssc JE Electrical

- Speed Control of DC Motor|Shunt, Series, Compound DC Motor Speed control

Latest Posts in EEE Made Easy

- Environment MCQ for RRB JE CBT 2|Objective Questions Environment for Competitive Exams

- RRB JE CBT 2 Computer Awareness Book Arihant|Objective Computer Awareness Book 2025

- RRB JE CBT 2 Exam Date 2025 Postponed|RRB JE CBT 2 Exam Date

- [PDF]RRB JE Result 03/2024 Cut off, Selected no of candidates for all regions

- [PDF]Final Answer Key Junior Instructor Mechanic Agricultural Machinery|643/2023 Solved Question paper

- Acoustics MCQs|Industries Extension officer|IEO 2025

- LASER MCQs| Industries Extension officer|IEO 2025