Electric Welding: Electric welding is the process of joining two metal pieces,by using electrical energy to generate heat at the point of welding in order to melt the joint.

Let’s start from the question: what is welding?

Welding is the process of joining two pieces of metal or non-metal together by heating them to their melting point.

Filler metal may or may not be used to join two pieces.

Download & Install EEE Made Easy App

The physical and mechanical properties of a material to be welded such as melting temperature, density, thermal conductivity, and tensile strength take an important role in welding.

Depending upon how the heat applied is created; we get different types of welding such as thermal welding, gas welding, and electric welding.

Welding is nowadays extensively used in automobile industry, pipe-line fabrication in thermal power plants, machine repair work, machine frames, etc.

aDVANTAGES AND DISADVANTAGES OF WELDING

Advantages of welding

Some of the advantages of welding are:

- Welding is the most economical method to permanently join two metal parts.

- It provides design flexibility.

- Welding equipment is not so costly.

- It joins all the commercial metals.

- Both similar and dissimilar metals can be joined by welding.

- Portable welding equipment are available.

Disadvantages of welding

Some of the disadvantages of welding are:

- Welding gives out harmful radiations and fumes.

- Welding needs internal inspection.

- If welding is not done carefully, it may result in the distortion of work-piece.

- Skilled welding is necessary to produce good welding

What is Electric Welding?

Electric welding is defined as the process of joining two metal pieces, in which the electrical energy is used to generate heat at the point of welding in order to melt the joint.

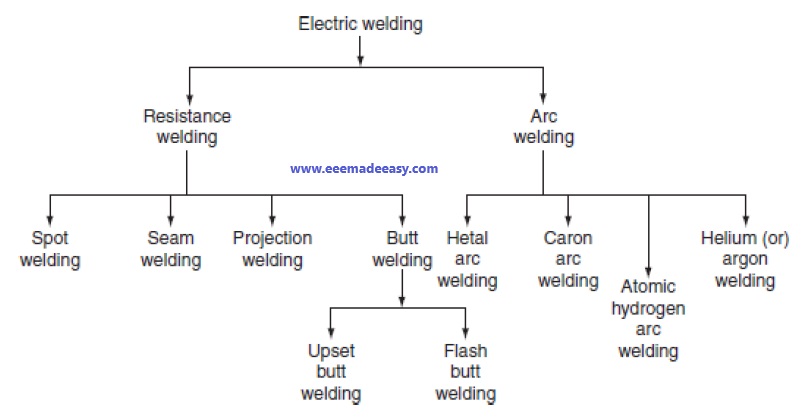

Types of Electric welding

The classification of electric welding process is shown:

Electric welding types are

- Resistance welding

- Spot welding

- Seam welding

- Projection welding

- Butt welding

- Upset but welding

- Flash butt welding

- Arc Welding

- Hetal arc welding

- carbon arc welding

- Atomic hydrogen arc welding

- Helium or Argon welding

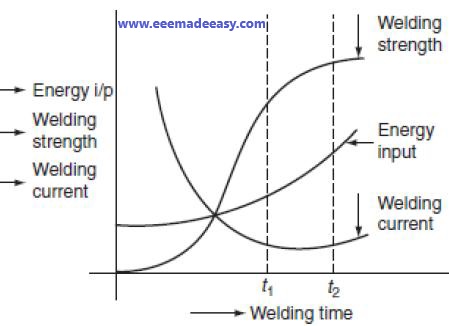

Choice of Welding time

The selection of proper welding process depends on the following factors.

o The type of metal to be joined.

o The techniques of welding adopted.

o The cost of equipment used.

o The nature of products to be fabricated

Resistance welding

Resistance welding is the process of joining two metals together by the heat produced due to the resistance offered to the flow of electric current at the junctions of two metals.

Types of resistance welding

Depending upon the method of weld obtained and the type of electrodes used, the resistance welding is classified as:

- Spot welding.

- Seam welding.

- Projection welding.

- Butt welding

Electric arc welding

Electric arc welding is the process of joining two metallic pieces or melting of metal is obtained due to the heat developed by an arc struck between an electrode and the metal to be welded or between the two electrodes as shown below.

In this process, an electric arc is produced by bringing two conductors (electrode and metal-piece) connected to a suitable source of electric current, momentarily in contact and then separated by a small gap, arc blows due to the ionization and give intense heat.

The heat so developed is utilized to melt the part of work-piece and filler metal and thus forms the weld.

In this method of welding, no mechanical pressure is employed; therefore, this type of welding is also known as ‘non-pressure welding’.

Types of electric arc welding

Various types of electric arc welding are:

- Carbon arc welding.

- Metal arc welding.

- Atomic hydrogen arc welding.

- Inert gas metal arc welding.

- Submerged arc welding.

Each of the welding methods will be explained in detail in next post. Please subscribe to notifications.

Read more on Electric Welding

- [Set 2]MCQ’s on Electrical Welding|Electrical Welding MCQ Questions and Answers|KSEB Sub Engineer

- [Set 1]MCQ’s on Electrical Welding|Electrical Welding MCQ Questions and Answers|KSEB Sub Engineer

- Electric Welding|Resistance welding Electric Arc Welding

- Resistance Welding|Types of Resistance Welding

- Electric arc welding|Types of Electric Arc welding

- Electric Arc length|Short,Medium, Long Arc

- Open Circuit voltage and Arc voltage|Polarity in arc welding

- Arc Welding Equipments|Arc Welding tools and Accessories

- Arc welding safety|shielded metal arc welding preparation & safety

- Methods of joining metals|Metal Joining Methods

- Types of welds|Weld types

- Applications of Welding|Welding Applications

Books on Welding

Join EEE Made Easy Telegram channel

Latest Posts in EEE Made Easy

- Environment MCQ for RRB JE CBT 2|Objective Questions Environment for Competitive Exams

- RRB JE CBT 2 Computer Awareness Book Arihant|Objective Computer Awareness Book 2025

- RRB JE CBT 2 Exam Date 2025 Postponed|RRB JE CBT 2 Exam Date

- [PDF]RRB JE Result 03/2024 Cut off, Selected no of candidates for all regions

- [PDF]Final Answer Key Junior Instructor Mechanic Agricultural Machinery|643/2023 Solved Question paper

- Acoustics MCQs|Industries Extension officer|IEO 2025

- LASER MCQs| Industries Extension officer|IEO 2025