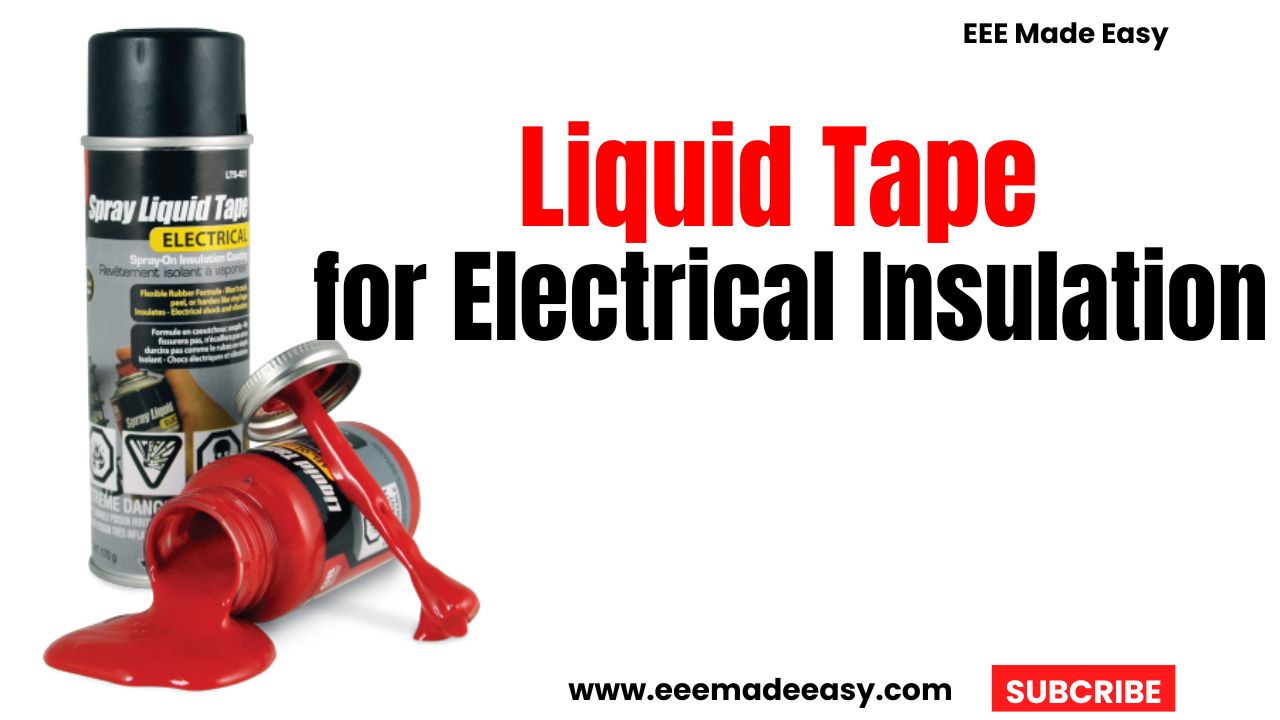

Liquid Tape is an air dry synthetic rubber coating that can be easily brushed on and exhibits excellent moisture, acid, alkaline, abrasion and dielectric resistance. It can be used on bare parts of Electric cable joints , where the regular insulation tape is not effective. Liquid Tape can be used to insulate, protect and color code.

Liquid Tape Types

Liquid Tape Brush type

Liquid Tape is available in red, black, green, and white.

It will not crack, peel, or harden and remains flexible even under extreme conditions.

Liquid Tape Spray type

Applications of Liquid Tape

Liquid Tape can be used in many applications including electrical connections for boats, trailers, RV’s, trucks, automobiles, timers, pool electrical, bilge pumps, sprinkler pumps, instruments, computers, circuit boards, switches, and will stop terminal screws from vibrating loose.

Use Liquid Tape to insulate, protect and color code.

How to use liquid electrical tape

Surface Preparation for applying liquid tape

- Wires, terminals, or all other surfaces must be clean, dry, and free of all oils, grease, wax and loose rust.

- Mix Well Before Use & Use Adequate Ventilation

- Stir gently with brush applicator cap to avoid producing bubbles before each use. Apply wet overlapping coats.

- Allow 10 – 20 minutes dry time (dry to the touch) before applying additional coats to desired thickness.

- A minimum of 2 – 3 coats are recommended for best results. Allow 24 hours for fully cure.

Caution

- Turn off power before starting electrical work and follow your local electrical codes.

- Minimum of 2 coats required (5+ mils) to assure good dielectric protection.

- Allow 4 hours dry time per coat before use. Allow overnight drying whenever possible and avoid excessive air movement, heat, or humidity.

- Always use proper ventilation and protection.

Gardner Bender, White LTG-400 Liquid Electrical Tape

Specification of Liquid Tape

Dielectric: (ASTM D-149) 1,400 v/mil

Solids (wt.): 24%

Tensile: (ASTM D-638) 430%

Cut resistance: (ASTM D-1044) very good

Shelf life: 1 year at 77˚F

Chemical resistance: acids, alkalines, pollutants – excellent petroleum’s – limited

Durometer shore A: (ASTM D-2240) 70

Salt Spray: (ASTM B-117) passed 1,000 hours

Weather ability: (ASTM G-53) 3 – 5 years

Temperature use range: -30˚F to 200˚F

Stone abrasion: (ASTM D-3170) excellent

Permealbility: (ASTM E-96) .03 grains/sq. ft./hr.

Viscosity range: 90 – 110 K.U. @ 77˚F (+/- 2˚F)

Join EEE Made Easy Whatsapp Channel

Where to buy liquid electrical tape

Liquid Tape FAQ’s

what is liquid electrical tape made of?

Liquid Tape is an air dry synthetic rubber coating

how to use liquid electrical tape?

liquid electrical tape can be used as liquid brush or spraying type

Applications of Liquid Tape?

Liquid Tape can be used in many applications including electrical connections for boats, trailers, RV’s, trucks, automobiles, timers, pool electrical, bilge pumps, sprinkler pumps, instruments, computers, circuit boards, switches, and will stop terminal screws from vibrating loos

What are the uses of liquid tape?

Liquid tape can be used to insulate, protect and color code.

Download & Install EEE Made Easy App

Latest Posts in EEE Made Easy

- Environment MCQ for RRB JE CBT 2|Objective Questions Environment for Competitive Exams

- RRB JE CBT 2 Computer Awareness Book Arihant|Objective Computer Awareness Book 2025

- RRB JE CBT 2 Exam Date 2025 Postponed|RRB JE CBT 2 Exam Date

- [PDF]RRB JE Result 03/2024 Cut off, Selected no of candidates for all regions

- [PDF]Final Answer Key Junior Instructor Mechanic Agricultural Machinery|643/2023 Solved Question paper

- Acoustics MCQs|Industries Extension officer|IEO 2025

- LASER MCQs| Industries Extension officer|IEO 2025