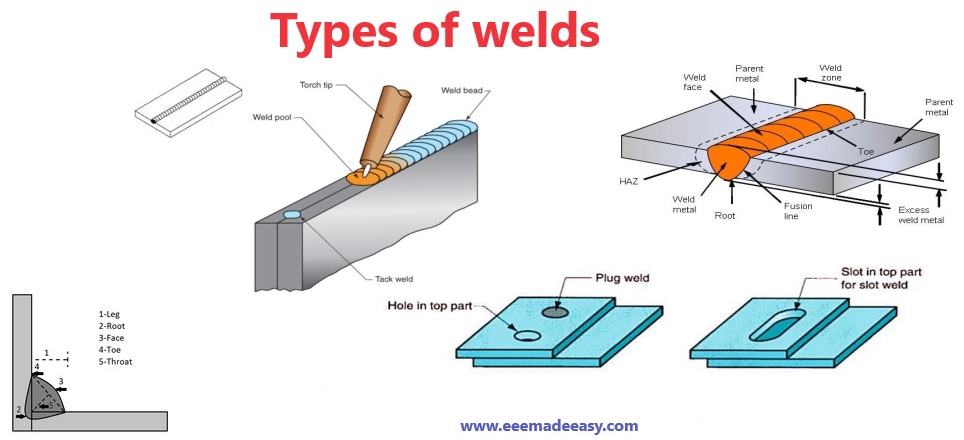

Different types of welds are used to get different welding joints .The different types of weld are Bead weld, Groove or butt weld, Fillet weld, Plug or slot weld.

Types of welds

- Bead weld

- Groove or butt weld

- Fillet weld

- Plug or slot weld

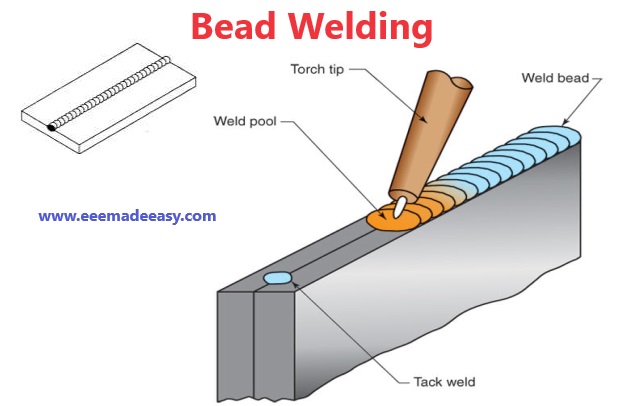

Bead weld

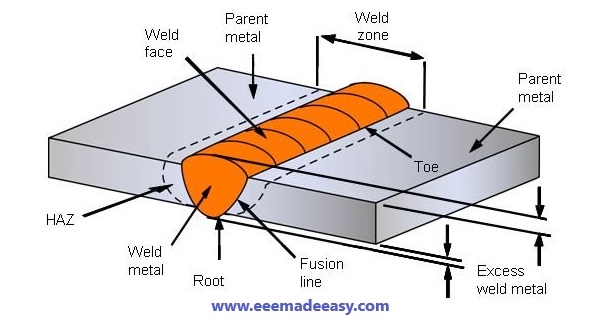

Bead weld is a type of weld composed of one or more stringer or weave beads deposited on an unbroken surface to obtain the desired properties and dimensions.

Join EEE Made Easy Whatsapp Channel

Butt weld or groove weld

Butt weld or groove weld is a weld made in the groove between two members to be joined as butt joint.

Groove welds are also done on T fillet joints if the plate thickness is more than 12mm.

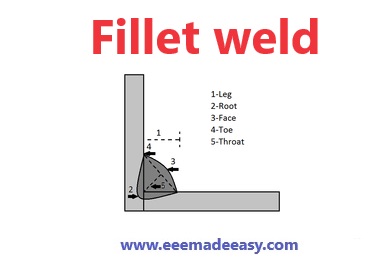

Fillet welds

Fillet weld is a weld, having a triangular cross-section, joining two surfaces at right

angle to each other such as:

- Lap joint

- Tee joint

- Corner joint

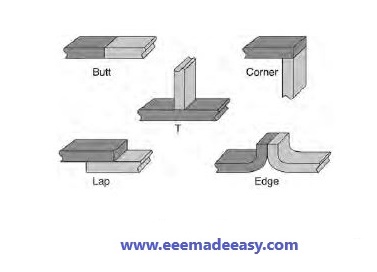

a) Butt joint. In this joint type, the parts lie in the same plane and are joined at their edges.

b) Corner joint. The parts in a corner joint form a right angle and are joined at the corner of the angle.

c) Lap joint. This joint consists of two overlapping parts.

d) Tee joint. In a tee joint, one part is perpendicular to the other in the approximate shape of the letter ‘‘T.’’

e) Edge joint. The parts in an edge joint are parallel with at least one of their edges

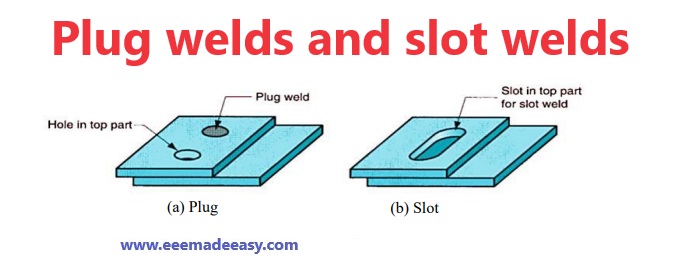

Plug welds and slot welds

Plug or slot welds are welds used to join two over-lapping pieces of metal by welding

through circular holes or slots.

Download & Install EEE Made Easy App

These welds are often used in the place of rivets.

a Plug welds and slot welds are used for attaching flat plates, as shown in Figure below, using one or more holes or slots in the top part and then filling with filler metal to fuse the two parts together.

Plug welds are placed in around holes and slots welds are place in elongated holes. In each case, the weld meatal is place in the hole up to a certain depth (partial penetration or full

penetration).

The penetration depth of plug or slot weld is difficult to inspect visually, so such welds are not often preferred

Plug and slot welds are used to:

1- Transmit shear in lap joint

2- Connect components of built up members (such as web doubter plates) to prevent

buckling.

3- To conceal connection for steel that are exposed to architectural reason

4- To add strength to connection with fillet welds

5- Neither plug nor slot welds should be used where tension force is normal to the

plane pf the faying surface

6- Nor should they be used to support cyclical loads

Download & Install EEE Made Easy App

Read more on Electric Welding

- [Set 2]MCQ’s on Electrical Welding|Electrical Welding MCQ Questions and Answers|KSEB Sub Engineer

- [Set 1]MCQ’s on Electrical Welding|Electrical Welding MCQ Questions and Answers|KSEB Sub Engineer

- Electric Welding|Resistance welding Electric Arc Welding

- Resistance Welding|Types of Resistance Welding

- Electric arc welding|Types of Electric Arc welding

- Electric Arc length|Short,Medium, Long Arc

- Open Circuit voltage and Arc voltage|Polarity in arc welding

- Arc Welding Equipments|Arc Welding tools and Accessories

- Arc welding safety|shielded metal arc welding preparation & safety

- Methods of joining metals|Metal Joining Methods

- Types of welds|Weld types

- Applications of Welding|Welding Applications

Books on Welding

Latest Posts in EEE Made Easy

- Environment MCQ for RRB JE CBT 2|Objective Questions Environment for Competitive Exams

- RRB JE CBT 2 Computer Awareness Book Arihant|Objective Computer Awareness Book 2025

- RRB JE CBT 2 Exam Date 2025 Postponed|RRB JE CBT 2 Exam Date

- [PDF]RRB JE Result 03/2024 Cut off, Selected no of candidates for all regions

- [PDF]Final Answer Key Junior Instructor Mechanic Agricultural Machinery|643/2023 Solved Question paper

- Acoustics MCQs|Industries Extension officer|IEO 2025

- LASER MCQs| Industries Extension officer|IEO 2025